Services

|

How Powder Coating WorksPowder coating is very much like it sounds in that a dry type of free-flowing powder coating is aimed at the object to be painted and adheres based on electrostatic charging that is then cured under heat. As a result of the process, the powder coating becomes a much stronger finish than conventional liquid paint, especially beneficial in outdoor uses and where the item may take an unusual amount of punishment such as appliances, chairs, bicycles, and numerous metal items. Liquid coatings need binders and fillers (solvents) to keep the liquid in suspension waiting for coating and requisite drying time in order to set. Powder coatings do not require the solvents and thus, end up being stronger and more versatile. The result of applying the coating electrostatically is the formation of a skin that is allowed to set as a stronger, longer lasting coating.than typical paint.

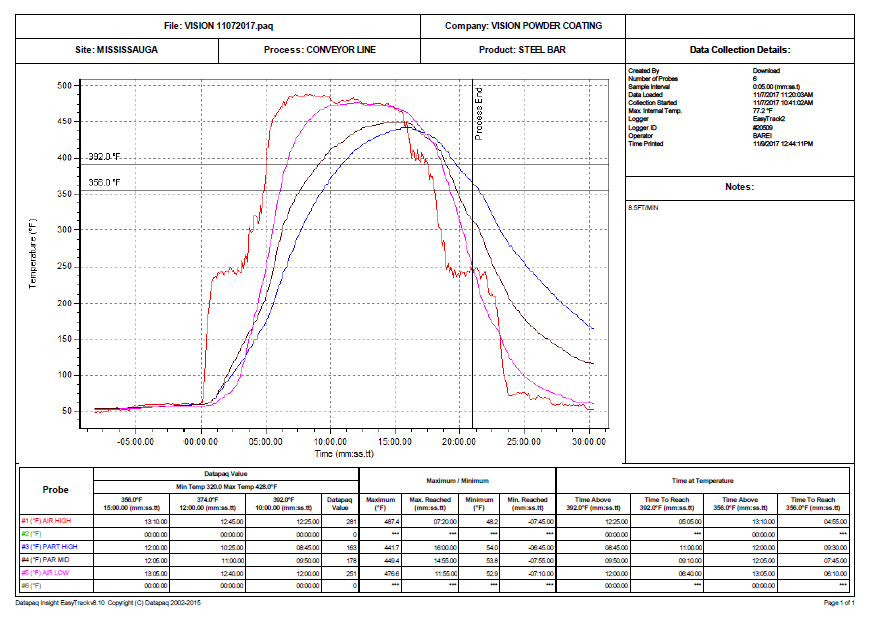

The ProcedureBoth powder coating and wet paint require proper cleaning of oils and sediment. With powder coating the spray is applied with a negative electrical charge the allows the powder to adhere willingly and evenly to the raw positively charged (grounded) metal. The item is then placed in a curing oven.where the powder is heated and gels, creating thermal bonds the powder particles together, which results in a hard finish with a smooth texture. . Paint is actually applied in a similar manner but with much less intensity and less of an electrical charge resulting in a thinner finish. .

AdvantagesPowder coating provides many advantages over liquid paint. The ability for powder to ap[plied with a high electrical charge when compared to paint allows for a superior bond that will last for a longer time as well as providing far a harder finish. When the coating of a metal object chips thins to reveal bare metal, the protection is gone. Bad things happen to metal when exposed so a harder finish is usually preferred. Powder coating is also easier to apply as there is no beading or dripping which can often be the case for liquid applications.

One of the advantages of liquid paint is the ease by which colours can be created and mixed. Liquid pigments can be mixed on the spot whereas powders need to be planned and manufactured as they don't readily 'blend'. This is not usually a problem; with some minor planning, colours will be always be available. The cost of powder coating is similar, if not less expensive than liquid finishing, and may be even less costly in the longer term as the finish will tend to last longer. And finally, powder coatings are actually eco-friendly when compared to liquid painting with the benefit of not needing solvents to maintain stability in raw material. |

Remember that coatings aren't just about decorating the final product. The finishes are meant to protect metal objects from UV sunlight and humidity which will eventually cause oxidization and rust. Even with coated finishes, time will allow the breakdown of these finishes as exposure to sunlight, heat and moisture breaks down the resins in both powder coatings and paint. You can notice that cars dull over the years from this process which is known as chalking as resins and pigments lose adhesion. The good news about powder coatings is that this breakdown is resisted for a much longer time than liquid paint.because of the lack of solvent in the powder finish.

SERVICE AREAS

Toronto Mississauga Markham Vaughan Brampton Aurora King City Richmond Hill Halton Hills |

|